HF Alkylation

Vogt is an approved manufacturer of HF valves for the UOP process,

Our products are listed on most of plants operators' AML for Alkylation service.

Vogt products for HF Alkylation service includes:

| Products | Size | Class |

|---|---|---|

| API602 - Forged Gate, Globe, Check | ½” – 4” | 150- 600 |

| API600 - Cast Gate, Globe, Check | 2” – 24” | 150- 600 |

| API609- Triple Offset Butterfly | 3” – 24” | 150- 600 |

| API599 - Lined Plug Valves | ½” – 24” | 150- 600 |

| DuEX Segmented Ball | ½” – 24” | 150- 600 |

| Bellows Seal Gate, Globe | ½” – 24” | 150- 600 |

What is an Alkylation Process?

A refining process used to enhance gasoline octane rating.

Inherent in several of these process systems is the use of hydrofluoric (HF) acid.

Special QA Requirements?

Yes. Vogt Alkylation valves are constructed on a Certified ISO 9001 QA Program to assure that all design, materials, quality, inspection and manufacturing details are met.

Special Test Requirements?

We test hydrofluoric acid (HF) valves with a test medium of mineral oil/kerosene to avoid the potential for water entrapment.

Water entrapment when combined with HF acid could cause accelerated corrosion in service.

Forged Steel Alkylation Valves

Forged Steel Alkylation Valves

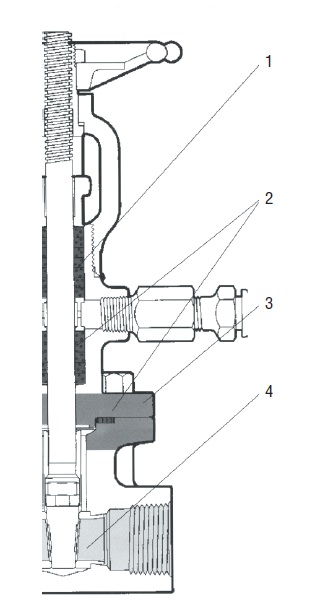

1. Double Packing Chamber?

Some systems engineers specify a valve designed with a double packing chamber, lantern ring and grease injector—particularly where hot or cold, full-strength HF acid is the flowing medium. The grease injector provides for a means to insert a compatible lubricant at the center of the packing chamber to assure smooth operation of the valve stem while the lubricant also augments the seal between the operating fluid and the atmosphere.

2. Packing And Gasket Filler Materials?

PTFE and flexible graphite packing have been effectively used in HF valve applications. PTFE is usually preferred in HF valve applications where temperatures remain at or below 500˚F. For temperatures above 500˚F flexible graphite is suggested. Gaskets are spiral wound with filler material identical to the packing material having the same designation.

3. Acid-Detecting Paint?

As an additional safety precaution some specifications require painting body/bonnet joint flange surfaces for the purpose of detecting acid leaks. This paint is usually a requirement only when traces of acid in the flow medium are present or when high acid concentration levels exist.

4. Full Port Valves?

Hydrofluoric acid, in high concentration, actually forms a protective film on carbon steel internal surfaces.

The use of a full port valve with its larger flow path minimizes fluid erosion of the “protective film” as the flow medium passes through the valve.

5. Other Applications?

Yes. Use this unique design of double packing chamber with grease sealant injector can be used when additional assurance against environmental emissions through valve packing is needed.